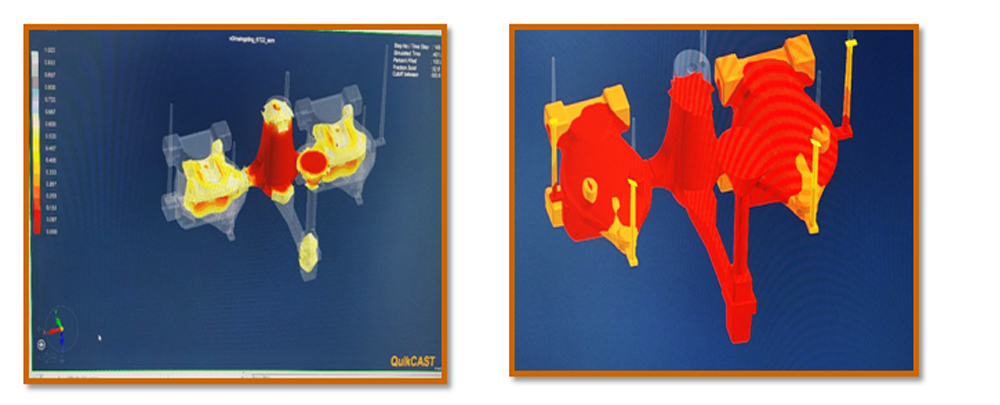

Inhouse Simulation Facility

All methoding designs are freezed using Simulation Software and 100% parts are developed by using simulation. Feeding system alterations are done & simulated unless satisfactory results are obtained to reach an optimum level. We consider all inputs about velocity of molten metal during mold filling, filling time and solidification time, which supports to locate flow related defects such as cold shut. Through simulation we predict the growth of the process without physically performing the process and how metal will behave as it enters a mold and cools. It adds confidence about the functionality of feeding system design.

Inhouse Pattern Manufacturing Facility

Inhouse Tooling facility available and it provides the facility for new pattern development, maintenance & repair of patterns. In developing the pattern, all inputs are considered e.g. simulation results, ECN, highlights of drawing, critical parameters, customer specific requirements, PFMEA and first time right approach.

Advance Manufacturing Equipments

ZOOM

UNIT-II

ZOOM

Tool Room

ZOOM

Automatic Sand Plant Panel

ZOOM

Sand Plant (Fully Automatic)

ZOOM

Pouring Line

ZOOM

Pattern Making

ZOOM

Melting With Advance Induction F/C

ZOOM

High Pressure Moulding Machine

ZOOM

Auto Charging System

ZOOM

Auto Box Closing System-

ZOOM

Auto Box Closing System

ZOOM

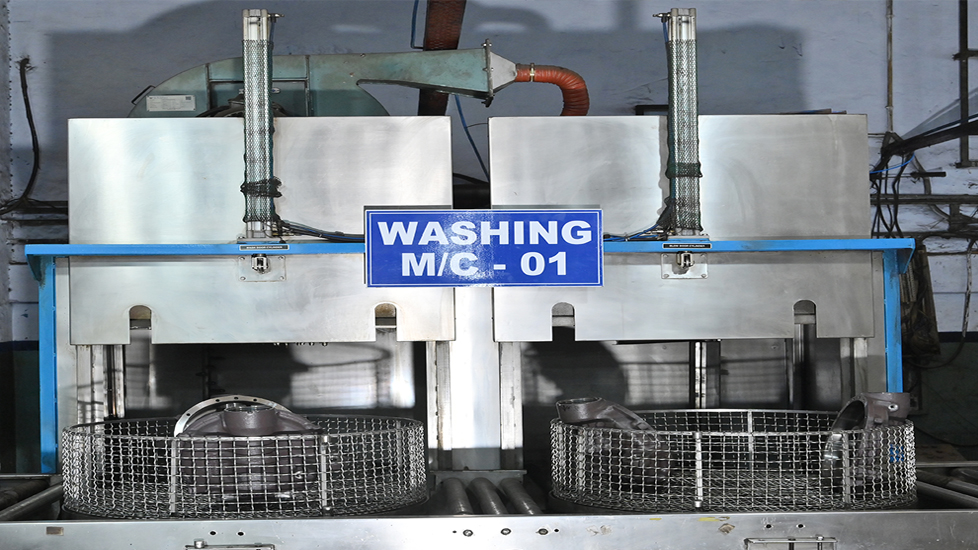

Washing Machine

ZOOM

Conveyorized Paint Shop

ZOOM

Conveyorized Paint Shop

ZOOM

Pouring Process

ZOOM

Pouring Line

ZOOM

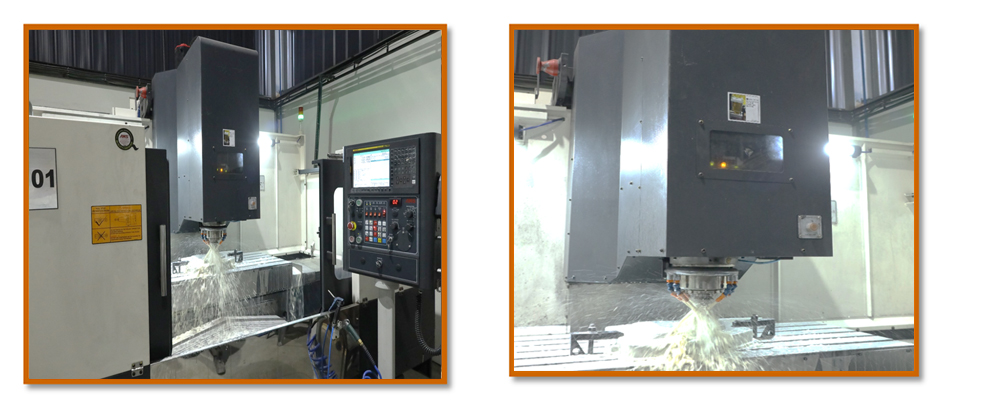

Machine Shop

ZOOM

High Pressure Moulding Line

ZOOM

Core Making Machine